The boat is now fibreglassed and ready for the next job!!

John

This is a journal of aggregated techniques, photos videos, and plans for Marine Modelers and Model Ship Builders. . My name is DaveMainwaring @ gmail.com. This blog started when I was building a semi-scale Star45 a model based on the International Star. WhyNot build scale, semi-scale static display, radio controlled models powered by Sail, Steam, Electric power for adults and toy boats for kids?

"John Fisher" is building Star 45's. He has provided a series of photographs taken as he builds the model from scratch.

These are posted to the blog along with his notes to help builders assemble the Star 45.

In the following posts you will find comments, notes. and his photographs

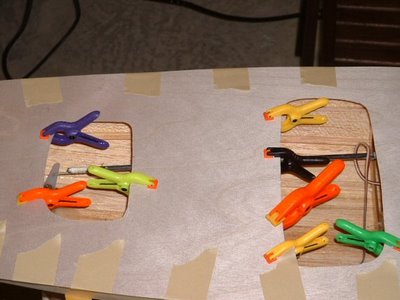

Photo's showing the building board and the first couple of steps for putting the frames together.

Building board is 3" wide 3/4" MDF that is glued/screwed together.

The notched balsa template is glued to the building board using a straight edge. Use a staight edge to make sure it stays straight.

AMYA Star 45 Class Rules, 2006, Rudder

6.1 Rudders may be constructed of wood, fiberglass, plastic, plastic laminates or metal. The exact shape is not specified, but they may not exceed 4 1/2 inches at the hull (fore and aft) 3 inches at the bottom, (fore and aft); and may not project more than 7 inches below the hull when measured at the post..

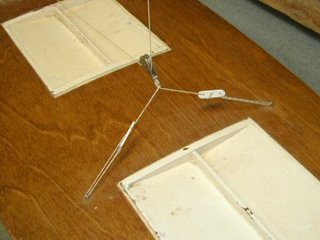

| To align the keel tubes John drills the holes in the center of the boat, this is easy to find since it is simply the middle of the king plank and the middle of the two keel planks. Then to align them so they are straight he placed a metal ruler along the two keel bolts or if a flat plate along the plate. Then look at where the end meets the transom. It should be off center by half the amount as the bolts/keel are thick. John does this on both sides to make sure it is centered. Once the bottom is aligned he tacks it in place with CA, then verify the alignment at the deck the same way. |

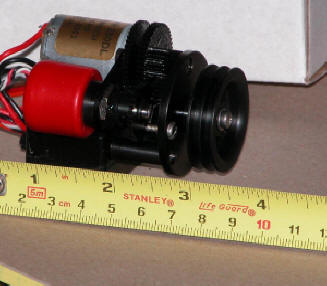

photo's courtesy of "Larry Ludwig" at www.LudwigRCYachts.com, Ludwig Mfg.

AMYA Star 45 Class Rules, 2006, Boom

4.0 BOOMS:

4.1 The main boom and jib club shall not exceed 5/8" when measured at the thickest point. Booms and jib clubs shall be constructed of wood, aluminum and/or fiberglass.

from John Fisher:

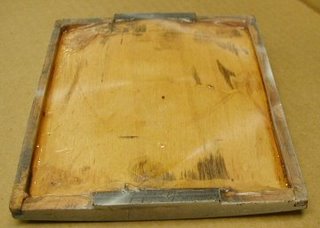

Attaching deck to hull