Well the boat is on its way and the mast has been stepped, now to finalise the sails etc

This is a journal of aggregated techniques, photos videos, and plans for Marine Modelers and Model Ship Builders. . My name is DaveMainwaring @ gmail.com. This blog started when I was building a semi-scale Star45 a model based on the International Star. WhyNot build scale, semi-scale static display, radio controlled models powered by Sail, Steam, Electric power for adults and toy boats for kids?

Phil Geren Sat, 25 Nov 2006 20:57:08 EST

STAR 45 CLASS

TECHNICAL COMMITTEE

November 2006 To December 2007

Table of Contents

Don Keeney, Class Secretary of the Star 45 Class of model yachts sanctioned by the American Model Yachting Association, announced at the National Championship Regatta held in October of 2006 that he plans to assist the Membership of the Class in achieving a clear, unambiguous, and uniform interpretation of the Rules. He also stated a goal to enhance the growth of participation in the Class.

To these ends Don formed the Star 45 Class Technical Committee of November 2006 through December 2007. The objectives, members, working processes, an an initial list of prioritized action items are set forth below.

The Technical Committee shall:

µ Ensure that the Star 45 Class Rules are:

o Capable of being clearly understood by all Class members without ambiguity;

o Subject to only one interpretation;

o Adequate to preserve the one-design principle of the Class, while allowing room for improvement in sailing performance

By:

o Formulating and publishing Guidelines for Rule Interpretation and Application (“GRI”);

o Submitting to the Class Secretary proposed Rule Amendments and New Rules;

µ Enhance growth in Class Membership by:

o Discovering and publishing corrections and clarifications to errors and ambiguities in the approved Star 45 reference and construction plans;

o Discovering and publishing Guidelines For Building And Tuning (“GBT”) Star 45 Model Yachts in order to assist a builder in achieving a competitive racing boat, at minimum cost, complying with the Rules, regardless whether building from scratch or from kit materials.

The Technical Committee shall comprise eight participants: the Class Secretary, Committee Chairman, and six Members. The Committee Chairman and the Members shall have voting rights.

The following people shall be directly involved in the business of the Technical Committee:

Class Secretary: shall participate in all discussions; shall take the final decision on all issues regarding the Rules after receiving the recommendation of the Committee. shall have no vote in Committee voting processes; shall, subject to his sole discretion, publish Guidelines for Rule Interpretation and Application received from the Technical Committee; shall, subject to his sole discretion, submit to the Class Membership for approval Rule Amendments and New Rules received from the Technical Committee;

Committee Chairman: shall recruit to fill vacancies on the Committee; shall chair discussions among Committee Members and administer voting processes; shall have voting rights; shall prepare the final wording of GRIs and GBTs based upon the consensus of the Committee; shall publish GBTs;

Committee Members: shall bring issues to the Committee for action; shall discuss and reach consensus, through simple majority vote on all issues; shall formulate Guidelines for Rule Interpretation and Application and submit these to the Committee Chairman for preparation of a final document; shall formulate, prepare, achieve consensus upon and submit to the Committee Chairman Guidelines For Building And Tuning Star 45 Model Yachts.

Present Committee Membership:

Class Secretary: Don Keeney, 1keyknee@281.com

Committee Chairman: Phil Geren, philgeren@aol.com

John Fisher, racer577@citystar.com

Dave Mainwaring, mainwaring@rcn.com

David Ramos, david@rcyachts.com

Peter Latournes, platournes@aol.com

Mel Holman, foxnlox@buckeye-express.com

Region 3 Candidate - being recruited

µ Discussion shall take place through postings of Email messages to:

star45technicalcommittee@mainzone.com

or messages posted while visiting this website:

http://mainzone.com/cgi/lyris.pl?enjter=star45technicalcommittee .

Posted messages are read at: http://mainzone.com/cgi/lyris.pl?enjter=star45technicalcommittee .

Please note that photos and attachments cannot be sent to the above.

Photos and attachments can be sent to: http://star-45.blogspot.com/ , where building information is being archived.

µ Consensus shall be by simple majority vote;

µ The quorum shall be the Committee Chairman plus 4 or 6 Members;

µ Guidelines for Rule Interpretation and Application shall be published by the Class Secretary as he sees fit;

µ Guidelines For Building And Tuning Star 45 Model Yachts shall be published at Star 45@yahoogroups.com , at star45houston.com , and at http://star-45.blogspot.com/ .

µ Preliminary performance targets for the Committee are to:

§ issue this Technical Committee organizational document for voting by the Committee on 26 November 2006;

§ issue one GRI per month;

§ issue the first GBT within three months.

1. Guidelines for Rule Interpretation and Application:

a. overhang of backstay chainplate, strut, boomkin or other device – how to measure

b. “hull” definition, wood, fiberglass

c. 1/4” or 3/8” bow bumper overhang

d. rudder profile and dimension limitations

e. jib numbering

f. obtain reference and constructing drawings additionally from Class Secretary (not just Ship’s Store)

g. fiberglass = fiber reinforced plastic, such as glass or other fiber cloth impregnated with hardened epoxy or polyester resin

h. Rule 1.4: rule to be waived if unable to be reasonably applied, such as, for example, if the deck or keel is attached, if verification by another Class member is inconvenient (requiring mailing the model, for example). Alternatively, Rule 1.4 to be deleted.

i. Hierarchy between Rules and Drawings

2. Guidelines For Building And Tuning Star 45 Model Yachts

a. Make available the best of the versions of the laser-cut frame files with instructions, online

b. Discuss if http://star-45.blogspot.com/ organization is the optimum for guiding beginners

c. Keel and bulb locations

d. Wings on rudders and bulbs

e. Glue recommendations

f. New building materials

g. New sources for woods, other materials

h. Jib tweakers

i. Jib twitchers

j. Drawings, correctd on CD

k. Camber recommendations for keels and rudders

l. Backstay tension calibrated for mast bend

m. Mast bend recommendations vs wind speed vs luff curve

n. Sheeting angles vs windspeed

o. Mast position vs wind speed

From: "John Fisher"

From: "John Fisher"

"John Fisher" is building Star 45's. He has provided a series of photographs taken as he builds the model from scratch.

These are posted to the blog along with his notes to help builders assemble the Star 45.

In the following posts you will find comments, notes. and his photographs

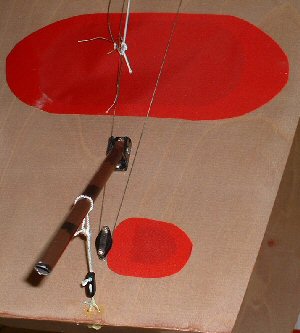

Photo's showing the building board and the first couple of steps for putting the frames together.

Building board is 3" wide 3/4" MDF that is glued/screwed together.

The notched balsa template is glued to the building board using a straight edge. Use a staight edge to make sure it stays straight.

AMYA Star 45 Class Rules, 2006, Rudder

6.1 Rudders may be constructed of wood, fiberglass, plastic, plastic laminates or metal. The exact shape is not specified, but they may not exceed 4 1/2 inches at the hull (fore and aft) 3 inches at the bottom, (fore and aft); and may not project more than 7 inches below the hull when measured at the post..

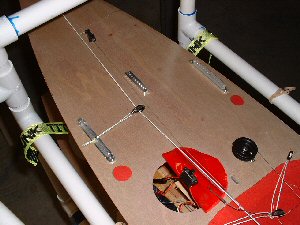

| To align the keel tubes John drills the holes in the center of the boat, this is easy to find since it is simply the middle of the king plank and the middle of the two keel planks. Then to align them so they are straight he placed a metal ruler along the two keel bolts or if a flat plate along the plate. Then look at where the end meets the transom. It should be off center by half the amount as the bolts/keel are thick. John does this on both sides to make sure it is centered. Once the bottom is aligned he tacks it in place with CA, then verify the alignment at the deck the same way. |

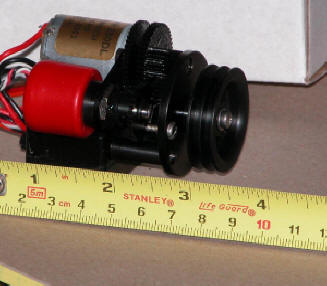

photo's courtesy of "Larry Ludwig" at www.LudwigRCYachts.com, Ludwig Mfg.