Model Sailboat Plans on line

Most browsers will allow you to right click and open the jpg images. You can then save them to your machine.

This set of plans are based on drawing from John Fisher 2006. John may have new and updated drawings available. Check with http://groups.yahoo.com/search?query=star45 membership required.

I want to thank J. Herrmann, www.graphicLanguageOnline.com, for his assistance in converting pdf's to jpg drawing, adding color to the templates and adding the grid to the final images

You can print these drawing to many different sizes.They are not necessarily to scale.

This is a journal of aggregated techniques, photos videos, and plans for Marine Modelers and Model Ship Builders. . My name is DaveMainwaring @ gmail.com. This blog started when I was building a semi-scale Star45 a model based on the International Star. WhyNot build scale, semi-scale static display, radio controlled models powered by Sail, Steam, Electric power for adults and toy boats for kids?

Search This Blog

5/03/2011

S45 Class Sailboat Plans {line drawings} on-line

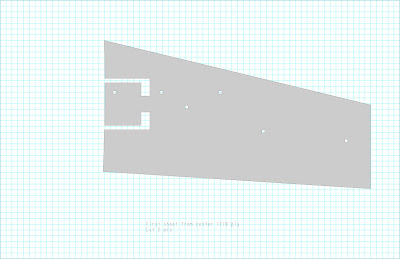

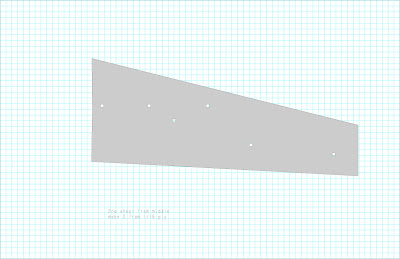

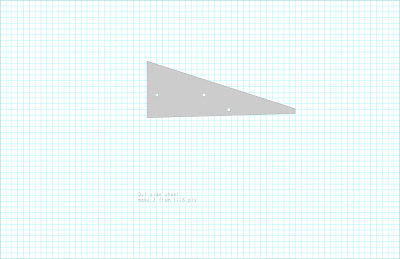

Star 45 Construction templates Keel fin

.jpg)

.jpg)

.jpg)

.jpg)

Building templates for S45 Keel fin.

Originals drawings are based on 1/16 ply.

Modeler may want to use different building materials for the fin.

Final keel fin will be shaped the builder. Also these are JPG drawing and print outs may require adjustments to get the templates to correct sizing.

The grid shown is set for 1/4 inch squares. So if you print the templates you can check the size by making sure the grid is a 1/4 square. If you want to scale the keel fins for another model you can change the print out to give you a different grid size.

This set of templates are based on bolt mounting. The grid makes it easy to add to the template to have the keel extend into the hull or extend into the keel bulb. Modeler's choice.

Most browsers will allow you to right click and open the jpg images. You can then save them to your machine.

This set of templates are based on drawing from John Fisher 2006. John may have new and updated drawings available. Check with http://groups.yahoo.com/search?query=star45 membership required.

I want to thank J. Herrmann, www.graphicLanguageOnline.com, for his assistance in converting pdf's to jpg drawing, adding color to the templates and adding the grid to the final images.

Star 45 Rudder Construction, using laser cut laminations

Star45 : Message: Re: [Star45] naca0009 rudder: "Re: [Star45] Photo's of naca0009 rudder

I am happy with how they turned out. I sent the production files to Stevens Monday, so you should be able to order a rudder if you need one. He doesn't have it posted yet, but if you call him he can cut them for you.

I built mine by clamping all the pcs together with the alignment pins in place (1/8 sq stock left over from stringers). Then CA'd it together with thin CA. I used my random orbital sander with 150 grit to shape it. Took about 15 min or so. With the different layers you can see if you are removing material evenly. Once sanded I sprayed the rudder with 3M 77, covered with 3 oz glass, one PC folding it over the leading edge so there is no seam on the leading edge. I then added resin and vac bagged in my handy food saver. The next day I pulled off the breather and peel ply, sanded smooth and varnished.

The glass is probably not needed since the core is made out of ply. I used the glass to ensure it is not coming apart and only adds another 10 min or so to do. With the vac bagging it is very smooth and uniform with only a little sanding required to remove the texture of the peel ply. I did buy a yard of breather and peel ply, but waxed paper with holes in it and paper towels can be substituted."

Drawings are available from the Yahoo Star45 group "files"

==

GET THAT TOPPING LIFT RIGHT (if you wanna go fast)!

The Star 45 R/C Model Sail Boat - Builders Journal

Wanna go fast? GET THAT TOPPING LIFT RIGHT

GET THAT TOPPING LIFT RIGHT (if you wanna go fast)!

By Phil Geren

Of all the go fast stuff I have learned from tuning experts over the past year, the most valuable, and the thing that has provided the most additional boat speed for my 13#-3.5oz Star 45 (the "Fat Lady") is how to get the Jib's topping lift set right. I am doing much better in my racing since learning this.

The curve of the leech of the Jibsail MUST resemble as closely as possible the curve of the leeward surface of the Mainsail when sighting from the foredeck. If the Jib's leech is flatter or fuller your boat will not attain its speed potential while beating and reaching.

The topping lift enables you to get the curves aligned. Tightening the topping lift makes the Jib's leech fuller, more curved. Loosening the topping lift makes the Jib's leech flatter. With a little practice you can get the curves to be identical.

Here's how:

Pull the Mainsail in to the beating position; Swivel the Jib boom with your finger (apply only lateral force, no upward or downward force on the Jib boom) so that when you sight from the foredeck and look up and down the curve of the windward surface of the leech of the Jibsail it is superimposed on the curve of the back (leeward) surface of the Mainsail.

Are the curves identical? If not, is the Jib's leech more curved?

If it is, loosen the topping lift.

If the Jib's leech is flatter, tighten the topping lift.

Make small adjustments. This is very sensitive, and you can get it right if you persevere.

Recheck the need for adjustment after every few heats of racing or if you change anything else.

On sailboats EVERYTHING is related to everything else, and you will need to readjust periodically to maintain your added speed.

Don't have a topping lift? INSTALL ONE NOW! You won't believe the improvement!

Weighing a keel-bulb while attached to a boat

The Star 45 R/C Model Sail Boat - Builders Journal: Weighing a keel while attached to a boat

Weighing a keel while attached to a boat

From "Larry Ludwig"

"Weighing a keel while attached to a boat can be done with a high degree of accuracy. You can test this out on a boat with a removeable keel. Lay the boat on it's side with the keelbulb on the scale with the keel parallel to the table. Then take the keel off and weight it and you will be amazed that they are nearly the same, as in within 95% or better."

Sailing Model, AMYA Star45 Class | Planking bottom of hull

From John Fisher:

Since it was requested here are a couple of photo's of planking the

bottom of my two wood/glass stars. photo 01 is the bottom of the first

star about half way done. Planks are 1/16 X 3/8 balsa. These were cut

from a 48" long sheet. Weigh your balsa before buying it. I would not

use a 3 X 48 sheet that weighed in at more than 22g. It takes 3 sheets

to cover the bottom and you could add another 1 to 1.5 oz by using

heavy balsa.

I started in the middle and worked to the outside. I sprayed the

shadows with kicker, then put down a plank, then added super fast CA to

hold it down. If the kicker was not dry enough it would cure before it

wicked into the joint which would cause the next plank to not fit

correctly. I had some variation in the planks, but once they were

glassed the bottom smoothed out quite a bit.

If I were to do another one I would add the half frames. I will be

adding them to the DXF files in the next couple of days for anyone

wishing to cut a set.

Picture shows the bottom after it was completely planked. On the

second boat I got a nice pattern on the bottom since the balsa sheets

had different grain structure. I sanded the sided flush and got the

bottom relatively smooth, but not perfect. With the balsa planks they

were flexible and if sanded too much you get thin spots at the frames.

The glass smoothed out inperfections. If doing a hard wood bottom the

planks should fit better than what I did with the balsa.

John Fisher 2006 August 15

Photograph by John Fisher

Since it was requested here are a couple of photo's of planking the

bottom of my two wood/glass stars. photo 01 is the bottom of the first

star about half way done. Planks are 1/16 X 3/8 balsa. These were cut

from a 48" long sheet. Weigh your balsa before buying it. I would not

use a 3 X 48 sheet that weighed in at more than 22g. It takes 3 sheets

to cover the bottom and you could add another 1 to 1.5 oz by using

heavy balsa.

I started in the middle and worked to the outside. I sprayed the

shadows with kicker, then put down a plank, then added super fast CA to

hold it down. If the kicker was not dry enough it would cure before it

wicked into the joint which would cause the next plank to not fit

correctly. I had some variation in the planks, but once they were

glassed the bottom smoothed out quite a bit.

If I were to do another one I would add the half frames. I will be

adding them to the DXF files in the next couple of days for anyone

wishing to cut a set.

Picture shows the bottom after it was completely planked. On the

second boat I got a nice pattern on the bottom since the balsa sheets

had different grain structure. I sanded the sided flush and got the

bottom relatively smooth, but not perfect. With the balsa planks they

were flexible and if sanded too much you get thin spots at the frames.

The glass smoothed out inperfections. If doing a hard wood bottom the

planks should fit better than what I did with the balsa.

John Fisher 2006 August 15

Subscribe to:

Posts (Atom)