Deck Sheer Strips -

Building the Inner Stem Part Two -

Installing the Outer Stem on a Kayak -

Cutting the Cockpit Recess -

Tapering the end of a strip to fit -

The final wood strip -

Cheater Strips on a Cedar Strip Boat -

Method for cleanly trimming excess fiber-glass -

Installing the First Strips on a Cedar Strip Kayak...

Sawing Cedar Strips for a Strip-Built Kayak - YouT...

Breaking Out Forms -

Hull & Deck Fused As Solid Fiberglass Unit -

Joining the Deck & Hull of a Kayak -

Basic Resin Infusion 030104 -

Vacuum Infusion of a Carbon Fiber Canoe -

How to make a Urethane Mold -

Mold and Part Making- Brushable Silicone, Spray Ha...

Epoxy Fiberglass Laminating Introduction -

...

5 Minute Epoxy Video -

Installing the Rails.wmv -

Making the hull Square and Level.wmv -

Wiring up the Hull Panels - 2.wmv -

Sealing the End Grain of the Scarfs with Epoxy -

Joining the Panels -

Installing the Exterior Glass Tape -

Layout and Smoothing of Glass Cloth -

Setting up Strip-Built Kayak Forms -

How I Built a Wood Strip Kayak -

Ripping and Sorting Strips for a Kayak -

Precise table saw cuts to make a puzzle -

Homebuilt Router Copier Lathe -

Preparing For Planking - Armed Virginia Sloop,

Hot-gluing a wooden strip in place -

Pictures and video from the 2012 Wooden Boats Fest...

Byrnes Model Machines - Ropewalk

Turn your Drill Press into a Lathe -

Drill Thickness sander -

12/8/12

Eugene L. Larson Shop Note: Constructing and Opera...

How to make a simple thickness sander

SMALL PARTS THICKNESS SANDER -

2011 IOM Alamo Classic -

This is a journal of aggregated techniques, photos videos, and plans for Marine Modelers and Model Ship Builders. . My name is DaveMainwaring @ gmail.com. This blog started when I was building a semi-scale Star45 a model based on the International Star. WhyNot build scale, semi-scale static display, radio controlled models powered by Sail, Steam, Electric power for adults and toy boats for kids?

Search This Blog

12/31/2012

11/01/2012

R/C model Friendship Sloop

10/24/2012

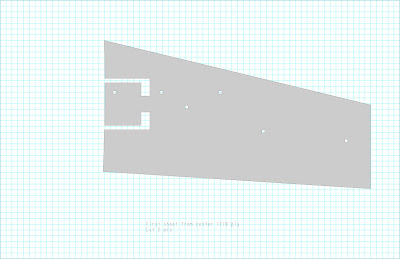

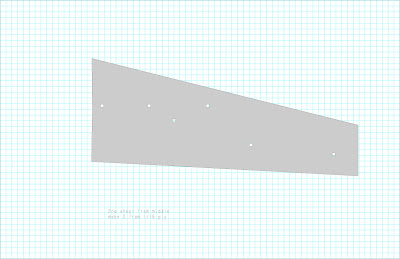

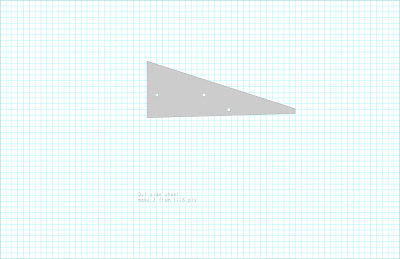

Keel Templates for S45 model sail boat

.jpg)

.jpg)

.jpg)

.jpg)

Building templates for S45 Keel fin.

Originals drawings are based on 1/16 ply.

Modeler may want to use different building materials for the fin.

Final keel fin will be shaped the builder. Also these are JPG drawing and print outs may require adjustments to get the templates to correct sizing.

The grid shown is set for 1/4 inch squares. So if you print the templates you can check the size by making sure the grid is a 1/4 square. If you want to scale the keel fins for another model you can change the print out to give you a different grid size.

This set of templates are based on bolt mounting. The grid makes it easy to add to the template to have the keel extend into the hull or extend into the keel bulb. Modeler's choice.

Most browsers will allow you to right click and open the jpg images. You can then save them to your machine.

This set of templates are based on drawing from John Fisher 2006. John may have new and updated drawings available. Check with http://groups.yahoo.com/search?query=star45 membership required.

I want to thank J. Herrmann, www.graphicLanguageOnline.com, for his assistance in converting pdf's to jpg drawing, adding color to the templates and adding the grid to the final images.

10/23/2012

9/12/2012

The following are a compilation of Lester Gilbert's materials, materials of others"

The Lester Gilbert pages are published with his permission and are "only intended for educational, model building guidance and discussion purposes User beware the writers assume no responsibility for anything. If you'd like to reprint, copy, or link to anything, please attribute words, diagrams, photos, spreadsheets, and software carefully and obtain permissions where appropriate so others know who was the source. The content is a compilation of my materials, materials of others and Lester Gilbert."

Lester Gilbert is at Learning Societies Lab, University of Southampton, Southampton SO17 1BJ, United Kingdom he may be reached by email at lg11@soton.ac

Adjusting the wind tunnel model

Lester Gilbert is at Learning Societies Lab, University of Southampton, Southampton SO17 1BJ, United Kingdom he may be reached by email at lg11@soton.ac

Adjusting the wind tunnel model

7/16/2012

Navy's legendary carrier USS Enterprise on final voyage – This Just In - CNN.com Blogs

Navy's legendary carrier USS Enterprise on final voyage – This Just In - CNN.com Blogs: Navy's legendary carrier USS Enterprise on final voyage

The legendary aircraft carrier USS Enterprise, America's oldest active-duty warship, was steaming in the Atlantic on Monday on the last deployment of its 50-year career.

The carrier and its crew of 3,100 left Norfolk Naval Station in Virginia on Sunday in the ship's 22nd deployment. The ship's air wing and other naval staff aboard add another 1,500 personnel.

The legendary aircraft carrier USS Enterprise, America's oldest active-duty warship, was steaming in the Atlantic on Monday on the last deployment of its 50-year career.

The carrier and its crew of 3,100 left Norfolk Naval Station in Virginia on Sunday in the ship's 22nd deployment. The ship's air wing and other naval staff aboard add another 1,500 personnel.

4/26/2012

Ron Graham - Papier mache puppets

Ron Graham - Papier mache puppets: Hydrated cellulose fibres - stuff of creativity

Insights into paper pulp

Casting puppet parts in paper pulp

Creating a puppet head from cast paper pulp parts

Creating the illusion

How to make and use a paper tearing machine .

How to make and use a pulp beater

Puppets exhibited 1

Puppets exhibited 2

Drawings on paper

Insights into paper pulp

Casting puppet parts in paper pulp

Creating a puppet head from cast paper pulp parts

Creating the illusion

How to make and use a paper tearing machine .

How to make and use a pulp beater

Puppets exhibited 1

Puppets exhibited 2

Drawings on paper

3/01/2012

AMYA Star45 Class rules as of 11.20.2009

American Model Yachting Association

AMYA Class Rules

1.0 Hull:

1.1 The Star 45 Class establishes as their approved plans a set of lines and drawings as the approved reference and construction plans for the class. These plans are scaled and appropriately modified for the use of modelers building a 45-inch model of the Star Boat. Existing plans supplied by kit manufacturers, etc. are grandfathered. New molds, plugs and scratch built models shall conform to the approved plans and specifications.

1.2 Hull length will be 45 inches (plus or minus one half (½) inch overall. (NOTE: this does not include any chain plate for backstay attachment, or ¼ inch bow bumper if used. However, if the chain plate is attached to the transom or overhangs the transom, it may not extend beyond the transom more than 3/8 of a inch.) Hulls may not be less than 11 inches nor exceed 12 inches in beam when measured at the widest point on the deck. (Rubrails are not included in measuring but will not exceed ¼ inch of thickness/width.)

1.3 In the event of a builder choosing to scratch or hand build a Star 45 Yacht, the builder must adhere to the class approved reference and construction drawings, as obtained from the AMYA Ships Store, as in the builders ability. A second consideration in scratch building is to ensure that safe and sound building practice be maintained.

1.4 All hulls will be constructed of wood or fiberglass or a combination of wood and fiberglass and be a minimum of 16 ounces when weighed before attachment of the deck and keel. This weight must be verified by another member of the Star 45 Class using the Class Measurement Form.

1.5 Decks shall be constructed of wood, fiberglass or plastic laminate material.

1.6 All hulls shall be the standard hard-chine hull. Hulls may be built with a sheer at scale height or with a sheer no more than one inch higher than scale (when measured at the point of maximum depth of sheer.)

1.7 All fiberglass and wood hulls will have a name plate permanently attached to the inside of the hull so as to be seen when the hatch cover is removed.

1.8 At or before its first Sanctioned Regatta the newly built model yacht must be measured using, as reference, the approved measurement form and signed by not less than the owner of the model yacht and one other member of the class. This measurement form shall become, with the registration card, a permanent record of this model yacht.

1.9 The AMYA Star 45 Class recognizes and approves the molds and manufacturer and/or kit packagers of Star 45 molded hulls and kits in existence at the time of approval of these specifications. These sources will be approved sources for the class. New manufacturers will be directed to submit the first of their product to the Class Secretary for approval.

1.10 No maximum weight is specified, however, no yacht will weigh less than 12 pounds when fully rigged ready to sail. This means with all gear, rigging, sails, radio components, batteries and ballast placed and secured on board.

1.11 Bow Bumpers are mandatory for all class registered STAR 45 yachts. Bow bumpers are limited to three eight's of an inch (3/8") overhang. Bow bumpers shall be excluded in the overall length measurement, whether recessed in or otherwise attached to the bow stem. Bow bumpers must be of resilient fabrication to minimize damage to another yacht in the event of a collision.

2.0 SAILS:

2.1 Sails may be of single or multi-paneled construction. Sail material shall be unrestricted.

2.2 All sails are to be cut to comply with the following maximum dimensions when measured by the procedure as outlined in the "AMYA Regulations". Dimensions shown are measured 'Edge of Cloth" to "Edge of Cloth" and are in inches.

2.3

MAIN JIB

Luff 62.75 42.50

Foot 25.50 15.75

Leech 65.50 37.00

Roach 2.00 0.50

Head 0.75 0.75

Foot Round 0.50 0.50

2.4 All sails, main and jib, will be cut with either a straight head to clew leech with no roach, or a fair curved head to clew leech with the maximum roach point occurring approximately one half the distance from the clew to head. Divide a straight line from the aft corners of the Clew and Head into four (4) equal sections. Then, for the Main Sail, maximum offset from edge of cloth for the Roach at the quarter points to be 1.75" and the offset at the mid-point to be 2.0". For the Jib, the offset at the quarter points to be 0.375" and at the mid-point to be 0.50". Sails cut with a straight leech at the maximum roach allowance are prohibited from use on the Star 45 Class Yacht.

2.5 The mainsail gooseneck or attachment will be attached to the Mast between 0.50 inch minimum to 4.0 inch maximum measured from the deck.

2.6 Battens are allowed on the mainsail but are restricted to 4 in number, equally spaced along the leech and may not exceed 8.50 inches in length. Battens are not permitted in the jib sail.

2.7 Sailmakers must conform to the above measurements.

2.8 Standing rigging is not specified except for the height of the jib stay attach point on the mast, which will not exceed 54 inches above the deck when measured from the deck at the mast step point, and mast head fittings are limited to a projection of 3.0 inches behind the mast. Control of standing rigging by other than manual manipulation (Hand Turning) is prohibited.

2.9 The Class Secretary maintains a master sail measurement template. Sail measurement templates shall be kept current with the class specifications as well as new motions passed by the rank and file. Templates shall be made of material consistent of lasting shape. Templates shall be made available for AMYA sanctioned regattas upon request from the hosting AMYA sanctioned club. Other non-sanctioned regattas may request templates which is subject to availability and discretion of the Class Secretary.

3.0 MAST:

3.1 Masts shall be made of wood or aluminum. Swing rigs, rotating and permanently bent masts are prohibited.

3.2 Masts shall not exceed ¾ inches square when measured at the thickest point of the mast. Maximum mast height shall be 70" when measured from the deck, inclusive of the crane. Rotating wind indicators and burgee staffs are not included provided the backstay is not attached to them in order to circumvent the 70" maximum mast height specification.

4.0 BOOMS:

4.1 The main boom and jib club shall not exceed 5/8" when measured at the thickest point. Booms and jib clubs shall be constructed of wood, aluminum and/or fiberglass.

5.0 RADIO CONTROL SYSTEMS:

5.1 Radio control systems of any number of channels may be used but the functions are limited to the rudder, sail control (jib sheets and main sheet) using no more than three servos. Control of the jib may be separate or may be combined in one function.

6.0 RUDDER:

6.1 Rudders may be constructed of wood, fiberglass, plastic, plastic laminates or metal. The exact shape is not specified, but they may not exceed 4 ½ inches at the hull (fore and aft) 3 inches at the bottom, (fore and aft); and may not project more than 7 inches below the hull when measured at the post.

7.0 KEELS AND BALLAST BULBS:

7.1 Keel will be of the style known as drop, and will be of the FIN and BULB type.

7.2 Keel fins may be solid or hollow and constructed of reinforced plastic, plastic laminates, fiberglass, wood or metal. (Note: Strength and integrity of the keel fins must be maintained whether built solid or hollow.) Keel fin shape is not specified but must follow the general shapes outlined on the reference drawing. However, keels will not be less than 6 inches nor more than 8 inches long (Fore and Aft) at the keel/hull junction, nor less than 4 inches nor more than 6 inches long (Fore and Aft) at the keel/ballast bulb junction.

7.3 Keels, keel fins and ballast bulbs may be removable, however, they may not be changed, interchanged, substituted or otherwise manipulated once any heat or series of heats in which scores will be compiled, has started. Mechanically movable keels or ballast bulbs are specifically prohibited from use in Star 45 Class Yachts.

7.4 Ballast bulbs may be constructed of any material not prohibited by the AMYA. The actual shape is left to the builder's discretion, but will not exceed 9.75 (9 ¾) inches from the front of the keel bulb to the rearmost point of the keel or bulb.

7.5 Total drop (length) of the keel fin/ballast bulb combination will not exceed 11.5 (11 ½) inches when measured from the keel/hull junction, before any fillers or streamlining is added.

7.6 Ballast may be made from any readily available material, such as poured lead, lead shot, etc. (Note: When using material such as lead shot, the mass must be solidified through the use of a bonding agent such as fiberglass or epoxy resin, plaster of paris, poured over and through in order to create a solid mass.)

7.7 Race directors may elect to use a template based on the construction plans to determine the keel length (depth).

7.8 Keel depth shall be measured from the center of the keel fin at the hull to the bottom of the ballast bulb. This measurement is from the edge of the bottom of the hull as it meets the side of the keel and should be determined during construction and before any fillet or fairing is added.

7.9 The Star 45 Class specifically excludes radio equipment, sail controls and batteries (power cells) from being considered ballast. This specification defines ballast as anything carried aboard the model for the main purpose of changing the weight distribution of the model and/or weight of the model. Ballast shall be fixed in place by gluing, fiberglassing, or bolting (bolts and screws).

7.9.1 Ballast may not be removed or relocated during any one regatta. The use of Velcro or similar quick release fasteners is prohibited as methods of mounting ballast.

8.0 DECK:

8.1 Deck construction shall be limited to wood, plywood, fiberglass reinforced plastic or plastic laminations (Formica). It may be covered with any material. Thin plastic films, such as MonoKote, are not allowed for decks except as coverings.

8.2 Hatches are not restricted in size, location, number or style, as long as deck strength and integrity are maintained.

9.0 DISTINGUISHING MARKS:

9.1 Each yacht shall carry on her main sail the class 5 point "STAR EMBLEM" and an assigned AMYA registration number. The star shall be at least 2 inches in size (measured from point to point across the flat of the star) and positioned above the registration number. Registration numbers shall be at least 3 inches in height and at least 3/8 inch thick. Both star and registration numbers will be placed on the upper half of the mainsail on both port and starboard sides of the mainsail and shall be positioned so as to be easily read from either side.

10.0 MANUFACTURERS PROCEDURES:

10.1 The following are procedures that must be followed by manufacturers, class secretaries and scratch builders, who are going to make more than one hull for sale.

10.1.1 The builder shall send to the class secretary proof of craftsmanship, hull by means of transportation of the builder's choice.

10.1.2 The class secretary will, upon receiving hull for measurement, notify the builder of the condition of the hull.

10.1.3 The class secretary will measure the hull.

10.1.4 When measuring hull the class secretary will request a Star 45 owner to assist with the measuring.

10.1.5 The class secretary will measure the hull, using the templates of the hull pictured in the approved plans.

10.1.6 The templates will be made of Plexiglas or wood (not Balsa).

10.1.7 The membership can request a copy of these templates by sending a request to the class secretary. These templates have been taken from the approved plans and are true and accurate.

10.1.8 The class secretary upon completion of the measuring will return the hull to the builder. The class secretary will also assign a number for the hull, if approved. Each hull will be measured regardless of condition. The manufacturer will keep in his possession a record of as to whom he sold hulls.

11.0 AUTHORIZATION FOR CLASS SECRETARY:

11.1 The class secretary shall be authorized to conduct class business such as granting interim approval to molds, manufacturers and similar approvals provided those actions are reported in the newsletter.

12.0 SPECIFICATIONS:

12.1 These specifications shall take precedent over any other document.

STAR 45 CLASS Model Yacht TECHNICAL COMMITTEE of 11/06 - 12/09

GUIDELINE FOR RULE INTERPRETATION AND APPLICATION

Clarification of the backstay attachment overhang of Star 45 Class Rule 1.2:

INTERPRETATION:

This phrase from the Rule: "...if the chain plate is attached to the transom or overhangs the transom, it may not extend beyond the transom more than 3/8 of an inch.)" SHALL BE INTERPRETED TO MEAN: NO PART OF ANY CHAIN PLATE, STRUT, BOOMKIN, OR OTHER MEANS, WHICH FORMS A PART OF THE BACKSTAY ASSEMBLY USED TO ATTACH THE BACKSTAY TO THE HULL, SHALL EXTEND FARTHER AFT THAN 3/8 OF AN INCH AFT OF AN IMAGINARY PLANE ALIGNED WITH THE TOP AFT EDGE OF THE TRANSOM AND PROJECTING UPWARD, PERPENDICULAR TO THE DECK SURFACE NEAR THE TRANSOM.

APPLICATION:

Extension may be measured by locating a carpenter's try square or right triangle on the deck surface adjacent to the transom. Place the square or triangle so that an edge of the square or triangle projects upward at a right angle to the longitudinal surface of the deck and intersects the aft edge of the transom, where it joins to the deck. Do this at the longitudinal center line of the hull or wherever the means is located along the transom. The chain plate, strut, boomkin or other means shall not extend farther than 3/8 of an inch past the aforementioned edge of the try square or right triangle.

Clarification of the definition of a hull in Star 45 Class Rule 1.4:

INTERPRETATION:

This phrase from the Rule: "All hulls...and be a minimum of 16 ounces when weighed before attachment of deck and keel." SHALL BE INTERPRETED TO MEAN: 16 ounces shall be the minimum total weight of the following parts: For fiberglass hulls: The hull shell, as withdrawn from the mold, plus the rail installed along the gunnels and stern for deck attachment, plus any reinforcement applied to the hull to strengthen the bottom of the hull at the keel/hull joint and at the mast post/hull joint. Nothing else is to be weighed, not the radio receiver/servo supports, nor keel box/tubes, nor mast post, nor rudder tube, nor rudder attachments, nor chain plate mounting pads, nor paint applied after withdrawing the hull from the mold, nor the deck, nor anything else.

For wood and wood/fiberglass hulls: The hull shell, as constructed, including frames, stringers, glue, waterproofing (not decorative paint) and any other internal structure that will not be removed prior to completing the construction of the boat and that is needed to strengthen and/or form the shape of the hull shell. Nothing else is to be weighed, not the radio receiver/servo supports, nor keel box/tubes, nor mast post, nor rudder tube, nor rudder attachments, nor chain plate mounting pads, nor paint applied to the hull shellS exterior, nor the deck, nor anything else.

These lists may be updated as needed in response to creative use of this Guideline.

APPLICATION:The hull will be weighed after removal from the mold (fiberglass hull) or the building board (wood or wood/fiberglass hull) and in a state of readiness for completing the construction of the boat (fiberglass hulls are waterproof, and therefore waterproofing may be added to wood or wood/fiberglass hulls prior to weighing). Weighing shall take place before the installation of : radio control equipment or its supports; rudder; keel; deck; decorative paint; anything else. If prohibited items are installed prior to weighing, the weight of the prohibited components will be added to the minimum weight. Example: if a radio tray is added to the frames before planking the sides/bottom and the tray weighed one oz before installation, the hull shall weigh 17 oz or more with the tray installed. If it is not reasonably convenient for an AMYA star class member to witness the weighing, a photo will be acceptable for Class registration purposes, provided that the photo clearly illustrates the hull on a scale indicating a weight of more than the minimum weight.

Clarification of the bumper thickness in Star 45 Class Rule 1.11 and 1.2

INTERPRETATION:This phrase from the Rule: " Bow Bumpers are mandatory for all class registered STAR 45 yachts. Bow bumpers are limited to three eight's of an inch (3/8") overhang… " and "…1/4 inch bow bumper if used..." SHALL BE INTERPRETED TO MEAN: All Star 45's shall have a bow bumper, and the bumper shall not protrude in any direction from the hull more than 3/8". On a boat with a cut- out for the bow bumper, an insert of non-resilient material will be considered part of the hull and not part of the bumper. Rule 1.11 shall be the governing rule for the bumper, and the 1/4" specification from Rule 1.2 shall be disregarded.

APPLICATION:The distance that a bumper protrudes from the hull shall be checked with a ruler with graduations of no less than 1/16" . Alternatively, a sharp object may be employed that penetrates the bumper material, but not the hull. In either case the measurement of protrusion of the outer surface of the bumper from the hull shall be no more than 3/8".

Clarification of the permanent mast bend Star 45 Class Rule 3.1

INTERPRETATION:This phrase from the Rule: "Swing rigs, rotating and permanently bent masts are prohibited." SHALL BE INTERPRETED TO MEAN: The Star 45 mast, standing free, without deflecting forces applied to it from any direction, may be curved or bent, but the deflection of the mast from its longitudinal axis, at any point along its length, shall not exceed one inch. This does not prevent a sailor from bending the mast with the standing rigging, to any extent, when the mast is installed on the boat. A bend at the mast head to extend the crane is not allowed.

APPLICATION:With the mast removed from the boat, or with standing rigging disconnected, sight along the longitudinal axis of the mast. If the mast is straight, no further measurement needs to be made.If the mast appears to be curved or bent, a string or elastic is run from the mast foot to the mast head, with no deflection of the line by the mast. The distance from the string or elastic surface to the mast surface shall not exceed one inch at any point along the length of the mast. If the mast has an S curve the measurer should situate the ends of the string or elastic aligned with the centerlines of the mast's head and foot. A side of the mast may have to be chosen which offers a unobstructed path from foot to head. The mast's centerline may not deviate from the string or elastic's centerline by more that one inch when measured at any location along the mast.. So if the line is placed on the aft edge of the head and foot of the mast, the aft edge of the whole mast must remain within 1” of the line from top to bottom. This is to be checked with a ruler with minimum graduations of 1/16”.

Clarification of rudder shape Star 45 Class Rule 6.1

INTERPRETATION:This phrase from the Rule: " The exact shape is not specified, but they may not exceed 4 1/2 inches at the hull (fore and aft) 3 inches at the bottom, (fore and aft); and may not project more than 7 inches below the hull when measured at the post."

SHALL BE INTERPRETED TO MEAN: The top of the Star 45 rudder shall be no more the 4 ½” wide, measured fore and aft along an imaginary line located 1/8" below the bottom of the boat at the rudder post and parallel to the hull. The bottom of the Star 45 rudder shall be no more than with 3" wide, measured as follows: for a straight bottom the bottom of the rudder shall be measured; for a curved bottom, the bottom shall be measured along an imaginary line located 1/4" above the lowest point of the rudder and parallel to the waterline. The shape of the rudder between its top and bottom is not regulated by this rule, and any shape may be employed. The thickness of the rudder is not regulated. The height of the rudder shall not exceed 7', measured between the lower most point of the rudder and the top of the rudder at the rudder post.

Please note that the rudder shown by the plan is effective and is a recommended design.

APPLICATION:With the rudder on the boat, the maximum depth is measured at the post, not to exceed 7”. The width of the rudder is measured with the measuring device oriented parallel to the hull and held 1/8" below the hull. The width of the rudder along the measuring device must not exceed 4 1/2". If the bottom of the rudder is straight then the width of the bottom of the rudder shall be measured along its bottom and shall not exceed 3". If the bottom is curved the width of the bottom of the rudder shall be measured with the measuring device oriented parallel to the waterline and held 1/4" above the lowest point of the rudder. The width along the measuring device shall not exceed 3".This can also be checked with a "go/no go" gage shaped like a U 1/4" deep and 3" wide.

Clarification of Sail Numbers Star 45 Class Rule 9.1

INTERPRETATION:This phrase from the Rule: "Registration numbers shall be at least 3 inches in height and at least 3/8 inch thick. Both star and registration numbers will be placed on the upper half of the mainsail on both port and starboard sides of the mainsail and shall be positioned so as to be easily read from either side. "

SHALL BE INTERPRETED TO MEAN: A Star 45 shall display its registration number on the main sail, in a font no less than 3” tall and have a width of the dark portion of the numbers to be no less than 3/8”. The numbers shall be in the upper half of the main with starboard over port. If numbers are displayed on the jib they shall be of the same size as the main and starboard over port. The registration number should be the hull number that was provided by the class secretary, but can be different than the hull number.

Due to the difficulty in reading sail numbers in large regattas it is recommended to add the registration number to the jib as well. The numbers on the jib should be displayed in the bottom half of the jib with starboard over port.

If a country designation is displayed it should be in the bottom half of the main and starboard over port.

APPLICATION: Numbers may be measured with the sails on or off the boat or rig with a ruler with a minimum dimension of 1/16”.

Clarification of Sail Numbers Star 45 Class Rule 1.7

INTERPRETATION:This phrase from the Rule: " All fiberglass and wood hulls will have a name plate permanently attached to the inside of the hull so as to be seen when the hatch cover is removed. "

SHALL BE INTERPRETED TO MEAN: A Star 45 shall have at a minimum the following information permanently attached to the hull: Star 45 Class, AMYA Registration number ____, hull weight ____, date ____, builder ____. The registration number should be the hull number provided by the class secretary when the boat is registered. More information can be included, but is not required.

APPLICATION: This is to be checked by removing the hatch and looking for the above information. The recommended way to do this is to print the information on a pc of paper, then attach it to the hull with epoxy so it can not be removed or damaged.

Clarification of rudder post location Star 45 Class Rule 1.3

INTERPRETATION:When the following phrase " In the event of a builder choosing to scratch or hand build a Star 45 Yacht, the builder must adhere to the class approved reference and construction drawings, as obtained from the AMYA Ships Store, as in the builders ability" from rule 1.3 is applied to the rudder post location, as measured on the measurement form and shown on the plans, this phrase.

SHALL BE INTERPRETED TO MEAN: That the rudder shaft or post shall pass through a point located on the centerline of the bottom of the hull 6" forward of the point where the center of the transom meets the center of the bottom of the hull.

A rudder shaft or post larger in diameter than the thickness of the rudder is prohibited.

APPLICATION:The rudder post location can be measured with the rudder on or off the hull. A ruler or tape measure shall have the origin located where the transom and hull bottom meet at the centerline of the bottom of the hull. The 6" point shall be located within the rudder post as it exits the hull. If the rudder location is measured with the rudder off the hull, the 6" point shall be located within the rudder tube.

Guideline for Interpretation and Application of Star 45 Class Rule 10

"Scratch builders" are those who build hulls “from scratch”, i.e. From wood or wood and fiberglass over frames, and those who build boats incorporating such hulls. Builders who build boats incorporating hulls purchased from approved manufacturers are not classified as scratch builders. With regard to scratch builders, Sections 10.1.1 and 10.1.3 of the Star 45 Class Rule 10 shall be interpreted as follows:

Rule 10.1.1 states: "The builder shall send to the class secretary proof of craftsmanship, hull by means of transportation of the builder's choice."

A scratch builder can comply with the requirement to “send …proof of craftsmanship” by:

· Conveying a scratch built hull to the class secretary by mail or other means of delivery, including presentation of the hull to the class secretary by the scratch builder or his delegate; or,

· Providing to the class secretary photographic and/or other evidence of the building of the scratch built hull which, at the sole discretion of the class secretary, is acceptable to the class secretary as evidence of proof of craftsmanship.

Rule 10.1.3 states: “The class secretary will measure the hull.”

The class secretary can comply with the requirement to “measure the (scratch built) hull” by:

· Measuring the actual hull; or,

· Verifying that the scratch builder used a frame design and spacing that has been measured and approved; or,

· Employing photographic and/or other evidence of the building of the scratch built hull, submitted by the builder, in order to measure the frames or the designs of the frames used by the scratch builder, to measure the positions in which the scratch builder placed the frames within the hull, and to make whatever other measurements the class secretary deems necessary in order to determine whether the hull complies with the Rules.

APPLICATION: A scratch builder is free to sell one scratch built hull or one boat incorporating a scratch built hull without that hull having passed the class secretary’s proof of craftsmanship and measurement tests described above.

If a scratch builder intends to sell more than one scratch built hull or more than one boat incorporating a scratch built hull, he or she must pass the class secretary’s proof of craftsmanship and measurement tests prior to selling the second hull or second boat.

After a scratch built hull from the scratch builder has passed the class secretary’s proof of craftsmanship and measurement tests described above (thereby becoming an approved hull), the scratch builder may build and sell further scratch built hulls and or boats incorporating such hulls without submitting evidence of proof of craftsmanship for such further hulls or boats providing that the same techniques and dimensions used for the approved hull are used for further scratch built hull. Measurement of such further hulls incorporated in boats shall be done pursuant to Rule 1.0.

GUIDELINE FOR INTERPRETATION AND APPLICATION OF STAR 45 CLASS RULE 7.2

INTERPRETATION: The following language in Rule 7.2: "Keel fin shape is not specified but must follow the general shapes outlined on the reference drawing. However, keels will not be less than 6 inches nor more than 8 inches long (Fore and Aft) at the keel/hull junction, nor less than 4 inches nor more than 6 inches long (Fore and Aft) at the keel/ballast bulb junction"

Shall be interpreted to mean:

The keel shall be a single foil with no openings or holes to reduce surface area. The keel fin's forward and aft edges shall be straight lines, from the keel/hull junction to the keel/ ballast bulb junction. The fin may be faired to the hull and/or the bulb with a fillet. The radius of the fillet is not limited, but all measurements are to be taken as if the fillet is not present. For this interpretation a straight line is no more than 1/16 inch variation from a string or line between the two points. With the boat oriented so that the plan waterline is horizontal, the forward edge of the keel fin shall be angled aft, in such a manner that the forward edge of the keel fin at its junction with the hull shall be located forward of the forward edge of the keel fin at its junction with the ballast bulb. The aft edge of the keel fin shall be vertical or angled aft. The fore-and-aft dimensions of the keel fin shall be: at the junction with the hull - between 6 inches and 8 inches; at the junction with the ballast bulb - between 4 inches and 6 inches.

APPLICATION:The keel width, that is its dimension in the fore-aft direction, shall be measured with a ruler or calipers with a minimum graduation of 1/16". Dimensions at the keel/hull or keel/bulb are minimum or maximum and any deviations above the maximum or below the minimum are not allowed. The maximum at the keel/hull is 8” and the maximum at the keel/bulb is 6”. The minimum at the keel/hull is 6” and the minimum at the keel/bulb is 4”. If the junction has a fillet, the measurement is taken at the intersection as if no fillet was there. This point is found by extending the line of the straight portion of the leading edge or the trailing edge until it meets the hull or bulb. This may be marked using a pencil or masking tape to facilitate measurement.

If there is a need to check for straightness of the fore and aft edges of the keel fin, a ruler or straight edge shall be placed against the fore and aft edges of the keel fin, so that one end of the ruler originates as closely as possible to the junction of the keel fin with the hull and so that the other end of the ruler rests against the highest point on the keel fin's edge or as close as possible to the keel fin's junction with the ballast bulb (whichever causes the largest gap between the keel fin's edge and the ruler.) The keel fin edge should be straight enough that a 1/16 inch diameter wire should not be able to pass between the straight edge and the keel fin at any point. If the junctions between the keel fin and the hull or the keel fin and the ballast bulb are filled-in with a fillet of material, to form a concave junction between surfaces, the straightness of the keel fin edge shall be measured between the fillets, that is by disregarding the curved fillet surfaces.

Due to the width limitations it is only necessary to verify the slope of the aft edge of the keel, as the forward edge will be aft sloped if the aft edge of the keel is vertical or aft swept. If verification of the sweep of the keel is necessary it may be done by either of two methods. Method one, A quick verification may be done by measuring the angle between the hull and fin. If the angle is less than 90 deg between the hull and the aft edge of the fin, the fin is aft swept. This can be done with a protractor or a 90 deg square. Method two, Level the hull so that it sits on the plan water line. The waterline location can be found by marking a point at 1-1/16” inches from the transom to hull junction and at 37-5/8” inches from the transom to hull junction. The hull is level when these two points are equal distance from a level surface. To verify the angle of the fin a plum bob is dropped from the keel/hull junction at the aft edge of the fin. If the junction has a fillet, the top of the plum bob line is located as if no fillet were there. To be aft or vertical swept the plum bob point at the bottom of the plumb bob line shall point to a position equal to or forward of the keel/bulb junction (or, if a fillet is present, forward of the place where the keel/bulb junction would be if no fillet were there.)

The Mainwaring keel profile is acceptable, being smaller than the maximum size and larger than the minimum dimensions.

Labels:

electric power,

model boat,

model yacht,

plastic,

R/C,

racing models.Star45,

radio control,

RC,

scale model,

scratch build,

shipmodel,

Star 45,

steam ships,

tall ships,

tow boat,

tug,

wooden

1/13/2012

article on the radio choices, servo choices, batteries etc by J fisher

Dave,

I will do a quick version now that I have access to a keyboard. j fisher jfisher577@gmail.com

Radio's:

Any of the new 2.4 ghz radios seem to work fine. The advantage is they all select an open channel before turning on or hop between channels while on to avoid interference. This includes the $30 hobby king radio. The question you need to ask yourself is do I want a computer radio or can I live with a radio without the ability to mix servos or adjust end points on servo travel. A computer radio will do both, a simple radio like HK will not. There are very few if any 2 channel stick radios left in production, buy a 4 to 8 channel and only use 2. You want Mode 2 radios as this puts the ratched on the left stick. Personally I have a high end 7 channel that I use for all my boats. I have one TX and it has a setup for each boat stored in the radio. It works well, but doesnt allow you to have multiple boats sailing at once. You could buy 10 Hobby King radios for what I paid for my TX. There are radios between the two price points, you need to ask yourself what features you need.

Servos:

There are lots of options, if you want cheap, hitech makes a nice drum winch along with some arm winches. They run about $50 and offer plenty of torque. The down side is they are slow. There are also a bunch of $20 to $30 cheap chinese winches. I have not tried any but I have read that the performance is mixed. Some work well, some do not. One case found that removing the o-ring on the output shaft solved the life issue.

The mid price but good performance option is digital 1/4 scale servo's. They run $150 to $200 and offer extremely fast speeds with 300+ ozin of torque. Most if not all are digital and can be programmed for up to 180 deg of travel. they are the lightest available. I have not used one, but they are commonly used on IOM's. I would make sure that you use pulleys on your sheets as constant drag on the sheets can cause excessive heat for the servo.

The last option is the RMG winch, I feel they are pretty much the standard which all the others are judged. They will rip the boat apart if something jams, good battery life, good speed and decent weight. Very programmable which eliminates the need for a programmable TX. Due to being mfg in Australia, the exchange rate effects price. I bought several last time we had a favorable rate, that made them about $80 cheaper than today.

Rudder servo can be any standard servo. Nothing special is needed.

Batteries:

Lipo or lithium polymer, very light, high discharge rates, fast charge and low self discharge. Down side is they need a Lipo charger and can burst into flames if over or under charged, they are also 8.4 volts when fully charged. This means you need a regulator for most radios. Cost is now low from places like HK, a 1000 mah pack is less than $10. I have used these since 2006 with no issues, you just have to take more care to make sure you dont discharge them below 3.3 volts per cell. The RMG winch has a built in regulator and low voltage cut off, which removes two of the big issues with Lipo's.

LiFe or lithium iron batteries are similar to Lipo but have slightly lower voltage, a bit higher weight. The advantage is they are more stable and will not burst into flames if abused. Down sides are similar to Lipo and you need a LiFe charger which may be different than the Lipo versions. These batteries are newer than the Lipo's.

Nimh or Nickel metal hydride a standard for years. Still available. They offer good battery life and reasonable weights. They are also robust in that they can be discharged to low voltages with no damage. The down sides are weight (heavier than Lipo Life), fast self discharge (have to charge before use), lower charge rates (may take several hours to charge if you want good charge retention). I no longer use Nimh due to the slow charge rates required. This is only an issue if you are doing multiple day regatta's. A good choice for anyone who is hard on batteries.

Nicad or Nickel cadmium the old standard of rechargeable batteries. Up side, cheap and durable. Down side, heavy, low capacity, slow charge rates and low charge rates. No reason to use them anymore as Nimh batteries have more capacity and are similar in other aspects.

I will do a quick version now that I have access to a keyboard. j fisher jfisher577@gmail.com

Radio's:

Any of the new 2.4 ghz radios seem to work fine. The advantage is they all select an open channel before turning on or hop between channels while on to avoid interference. This includes the $30 hobby king radio. The question you need to ask yourself is do I want a computer radio or can I live with a radio without the ability to mix servos or adjust end points on servo travel. A computer radio will do both, a simple radio like HK will not. There are very few if any 2 channel stick radios left in production, buy a 4 to 8 channel and only use 2. You want Mode 2 radios as this puts the ratched on the left stick. Personally I have a high end 7 channel that I use for all my boats. I have one TX and it has a setup for each boat stored in the radio. It works well, but doesnt allow you to have multiple boats sailing at once. You could buy 10 Hobby King radios for what I paid for my TX. There are radios between the two price points, you need to ask yourself what features you need.

Servos:

There are lots of options, if you want cheap, hitech makes a nice drum winch along with some arm winches. They run about $50 and offer plenty of torque. The down side is they are slow. There are also a bunch of $20 to $30 cheap chinese winches. I have not tried any but I have read that the performance is mixed. Some work well, some do not. One case found that removing the o-ring on the output shaft solved the life issue.

The mid price but good performance option is digital 1/4 scale servo's. They run $150 to $200 and offer extremely fast speeds with 300+ ozin of torque. Most if not all are digital and can be programmed for up to 180 deg of travel. they are the lightest available. I have not used one, but they are commonly used on IOM's. I would make sure that you use pulleys on your sheets as constant drag on the sheets can cause excessive heat for the servo.

The last option is the RMG winch, I feel they are pretty much the standard which all the others are judged. They will rip the boat apart if something jams, good battery life, good speed and decent weight. Very programmable which eliminates the need for a programmable TX. Due to being mfg in Australia, the exchange rate effects price. I bought several last time we had a favorable rate, that made them about $80 cheaper than today.

Rudder servo can be any standard servo. Nothing special is needed.

Batteries:

Lipo or lithium polymer, very light, high discharge rates, fast charge and low self discharge. Down side is they need a Lipo charger and can burst into flames if over or under charged, they are also 8.4 volts when fully charged. This means you need a regulator for most radios. Cost is now low from places like HK, a 1000 mah pack is less than $10. I have used these since 2006 with no issues, you just have to take more care to make sure you dont discharge them below 3.3 volts per cell. The RMG winch has a built in regulator and low voltage cut off, which removes two of the big issues with Lipo's.

LiFe or lithium iron batteries are similar to Lipo but have slightly lower voltage, a bit higher weight. The advantage is they are more stable and will not burst into flames if abused. Down sides are similar to Lipo and you need a LiFe charger which may be different than the Lipo versions. These batteries are newer than the Lipo's.

Nimh or Nickel metal hydride a standard for years. Still available. They offer good battery life and reasonable weights. They are also robust in that they can be discharged to low voltages with no damage. The down sides are weight (heavier than Lipo Life), fast self discharge (have to charge before use), lower charge rates (may take several hours to charge if you want good charge retention). I no longer use Nimh due to the slow charge rates required. This is only an issue if you are doing multiple day regatta's. A good choice for anyone who is hard on batteries.

Nicad or Nickel cadmium the old standard of rechargeable batteries. Up side, cheap and durable. Down side, heavy, low capacity, slow charge rates and low charge rates. No reason to use them anymore as Nimh batteries have more capacity and are similar in other aspects.

Subscribe to:

Comments (Atom)