John F. Howard (Star-45 discussion forum, July 31, 2006)

"Gorilla Glue does foam a bit, but nothing like foam-in-a-can and has minimum stink. Forget trying to smooth things out, the foam is very, very sticky and keeps growing until it sets up (about an hour) at which point it will still be a little soft (keep clamped for 3-4 hours). Any squeeze/foam out once hard, can be cut, chiseled or sanded smooth. Run a strip of tape along the edge of the glue line and most of the foam out will end up on the tape. The best joints are tight ones that use a minimum of glue. For narrow or thin pieces (planking), squeeze out a little puddle (just enough to use in 15-20 minutes) and use a Popsicle stick to spread along the edges. Wear gloves, the stuff stains and is sticky. GG is great for laminating larger areas (spread with an old credit card or playing card)."

"If you use epoxy resin such as West Systems (best, you can adjust the cure rate with the different hardeners) or one of the 30-minute or longer (5-15 minute never gets hard and remains rubbery) such as sold by Great Planes or Tower, stink will not be a problem. The polyester resin does STINK in a big way, it what you can smell in a new fiberglass hull.

CA glues are ok for "tacking" stuff in place until the epoxy sets up, but watch the fumes. CA will fail if used in a wet location for long and also cause a problem with the wood accepting stain. Work with plenty of ventilation and or respirator and wear gloves with any of the above glues and resins, staining of the skin and sensitivity, either skin and or breathing can occur."

"These are base on my experience with the glues mentioned (full size boats, cabinet work and models). Yellow glue such as Titebond or Elmers Carpenter Wood Glue (not waterproof) works fine when encapsulated with epoxy (cedar strip canoe builders use it all the time)."

{ http://groups.yahoo.com/group/Star45/ }

Phil Geren adds a warning note about Glue Fumes:

I have a serious allergic reaction to CA fumes - causes fluid to build up in the lungs, like pneumonia. I still use it, but with a fan blowing air between me and the work. Trying to avoid it.

Phil Geren on Gorilla Glue:2006 August 1

Is it rock hard or rubbery when dry?

I bought some, but have the same reservations as Dave M about foaming, trimming, and sanding. If it doesn't sand well, the finished product won't be as good as what I am aiming for.

This is a journal of aggregated techniques, photos videos, and plans for Marine Modelers and Model Ship Builders. . My name is DaveMainwaring @ gmail.com. This blog started when I was building a semi-scale Star45 a model based on the International Star. WhyNot build scale, semi-scale static display, radio controlled models powered by Sail, Steam, Electric power for adults and toy boats for kids?

Search This Blog

7/31/2006

7/14/2006

Mast Fittings for Star 45 R/C model sail boat

John Fisher's mast jack is pretty simple. He made a fitting that went in the bottom of the mast that was threaded 8-32. Then He cut down a brass nut from Lowe's and soldered it to a 8-32 bolt. This fits into the mast step and threads into the bottom of the mast. He is going to add a jam nut since the rig seemed to slowly lose tension as he sailed. The lock nut will be another cut down brass nut or a pc of 1/16 aluminum that is threaded 8-32.

Now John's parts are pretty fancy and without a lathe and CNC mill would be hard to make. The quick and easy way to make the same parts is to glue a wood block into the bottom of the mast, then use a blind nut as the thread for the mast jack. JB weld bonds well to aluminum and I would recommend it for gluing in the wood block.

For rig adjustment John would set the shrouds just tight enough that I had to undo the jib from the deck to move the rig. So he gets the shrouds set to have the mast straight, then put it in the right position for the wind speed, then add tension by unscrewing the mast jack. By having the rig set up this way you do not need to adjust your shrouds when moving the rig fore or aft or to change the tension in the forestay.

Here are som eother fittings courtesy of "Larry Ludwig" at www.LudwigRCYachts.com, Ludwig Mfg.

7/09/2006

GRP, Vacuum bagging, Fiberglass, Carbon Fiber , Dynel

Stuff you need to know:

Breather fabric is a lightweight, polyester blanket that provides excellent air passage within the vacuum envelope while it absorbs excess epoxy.

60" wide x 2.7 yd, 60" wide x 10 yd. 60" wide x 200 yd rolls:

Release Fabric is a tough, finely woven nylon fabric treated with a release agent. It is used to separate the absorber, breather and vacuum bag from the laminate in vacuum bagging operations. Excess epoxy bleeds through and is peeled from the cured laminate along with the release fabric. Peels easily and leaves a smooth textured surface, ready for bonding or finishing. 60" wide x 2 yd,. 60" wide x 10 yd rolls

Vacuum Bag Film is a Clear, heat-stabilized, modified nylon resin film, tough, stretchable film for high vacuum pressures. 60" wide x 2 yd, 60" wide x 10 yd,60" wide x 20 yd. 60" wide x 333 yd rolls:

Vacuum Bag Sealant; a mastic tape sealant for airtight seals between vacuum bags and molds. Easy to work with around difficult angles, patching small leaks in the system. 1/2" wide x 25' rolls:

Techniques Book on Vacuum Bagging, West System publishes this definitive guide to the principles and application of vacuum bagging techniques for laminating composite materials

with epoxy.

Fiberglass Mat is a Chopped Strand Fiberglass Mat, Offers great conformability with low cost.

Veil Mat 0.09 oz/sq ft

Fiberglass Mat, 3/4 oz/sq ft, 1.5 oz/sq ft, 2.0 oz/sq ft

Fiberglass Cloth 4-, 6- and 10-oz per square yard.

Dynel Fabric is a popular laminate fabric with great abrasion resistance used for museum-quality restoration work on wooden boats. It's strong and supple like a true woven fabric, with no fibers to irritate your skin.

Size Weight, 5 oz

Carbon Fiber lightweight, strong composite can strengthen any project while adding minimal weight.

Plain Weave 5.8 oz

Twill Weave 5.8 oz

Unidirectional 9 oz

Carbon Fiber Tape a unidirectional reinforcing tapes are used

to improve tensile strength and stiffness in one direction with minimal weight.

--

You can learn a lot about boat building by reading catalogs for example: www.jamestowndistributors.com/

Many of the same materials are also used in model boat building.

The Jamestown site has several links to model builders, AMYA and other organizations

Breather fabric is a lightweight, polyester blanket that provides excellent air passage within the vacuum envelope while it absorbs excess epoxy.

60" wide x 2.7 yd, 60" wide x 10 yd. 60" wide x 200 yd rolls:

Release Fabric is a tough, finely woven nylon fabric treated with a release agent. It is used to separate the absorber, breather and vacuum bag from the laminate in vacuum bagging operations. Excess epoxy bleeds through and is peeled from the cured laminate along with the release fabric. Peels easily and leaves a smooth textured surface, ready for bonding or finishing. 60" wide x 2 yd,. 60" wide x 10 yd rolls

Vacuum Bag Film is a Clear, heat-stabilized, modified nylon resin film, tough, stretchable film for high vacuum pressures. 60" wide x 2 yd, 60" wide x 10 yd,60" wide x 20 yd. 60" wide x 333 yd rolls:

Vacuum Bag Sealant; a mastic tape sealant for airtight seals between vacuum bags and molds. Easy to work with around difficult angles, patching small leaks in the system. 1/2" wide x 25' rolls:

Techniques Book on Vacuum Bagging, West System publishes this definitive guide to the principles and application of vacuum bagging techniques for laminating composite materials

with epoxy.

Fiberglass Mat is a Chopped Strand Fiberglass Mat, Offers great conformability with low cost.

Veil Mat 0.09 oz/sq ft

Fiberglass Mat, 3/4 oz/sq ft, 1.5 oz/sq ft, 2.0 oz/sq ft

Fiberglass Cloth 4-, 6- and 10-oz per square yard.

Dynel Fabric is a popular laminate fabric with great abrasion resistance used for museum-quality restoration work on wooden boats. It's strong and supple like a true woven fabric, with no fibers to irritate your skin.

Size Weight, 5 oz

Carbon Fiber lightweight, strong composite can strengthen any project while adding minimal weight.

Plain Weave 5.8 oz

Twill Weave 5.8 oz

Unidirectional 9 oz

Carbon Fiber Tape a unidirectional reinforcing tapes are used

to improve tensile strength and stiffness in one direction with minimal weight.

--

You can learn a lot about boat building by reading catalogs for example: www.jamestowndistributors.com/

Many of the same materials are also used in model boat building.

The Jamestown site has several links to model builders, AMYA and other organizations

7/06/2006

Star 45 R/C model sail boat Hulls, tips tricks | Class rules

Billie Geisler's comments on building Cedar Hulls,2006 August 1:

I build hulls from cedar rather than balsa. I find a clear, straight grained dog-eared fince picket at Lowes, Home Depot, etc. I cut the rough edges and flats off with a 10 inch table saw, rough cut the planks for the hull, then use a 3 inch table saw from Micro- mark to cut the final planks. I think that cedar is stronger than balse, and I don't think it soaks up as much epoxy. Epoxy is weight. My hulls weigh about the same as a fiberglass hull, and don't oil can.

The plastic sacks that the newspaper is in when it hits your drive is useful as gloves. The epoxy doesn't disolve them. Also, you can cut up the newspaper plastic sack and use to keep the hull from sticking to your clamps. These sacks are also good for picking up dog crap off your lawn, or any other nasty stuff. Just check for holes before using. :-)

AMYA Star 45 Class Rules, 2006, 1.0 Hull:

1.1 The Star 45 Class establishes as their approved plans a set of lines and drawings as the approved reference and construction plans for the class. These plans are scaled and appropriately modified for the use of modelers building a 45-inch model of the Star Boat. Existing plans supplied by kit manufacturers, etc. are grandfathered. New molds, plugs and scratch built models shall conform to the approved plans and specifications.

1.2 Hull length will be 45 inches (plus or minus one half (1/2) inch overall. (NOTE: this does not include any chain plate for backstay attachment, or 1/4 inch bow bumper if used. However, if the chain plate is attached to the transom or overhangs the transom, it may not extend beyond the transom more than 3/8 of a inch.) Hulls may not be less than 11 inches nor exceed 12 inches in beam when measured at the widest point on the deck. (Rubrails are not included in measuring but will not exceed 1/4 inch of thickness/width.)

1.3 In the event of a builder choosing to scratch or hand build a Star 45 Yacht, the builder must adhere to the class approved reference and construction drawings, as obtained from the AMYA Ships Store, as in the builders ability. A second consideration in scratch building is to ensure that safe and sound building practice be maintained.

1.4 All hulls will be constructed of wood or fiberglass or a combination of wood and fiberglass and be a minimum of 16 ounces when weighed before attachment of the deck and keel. This weight must be

verified by another member of the Star 45 Class using the Class Measurement Form.

1.5 Decks shall be constructed of wood, fiberglass or plastic laminate material.

1.6 All hulls shall be the standard hard-chine hull. Hulls may be built with a sheer at scale height or with a sheer no more than one inch higher than scale (when measured at the point of maximum depth of sheer.)

1.7 All fiberglass and wood hulls will have a name plate permanently attached to the inside of the hull so as to be seen when the hatch cover is removed.

1.8 At or before its first Sanctioned Regatta the newly built model yacht must be measured using, as reference, the approved measurement form and signed by not less than the owner of the model yacht and one other member of the class. This measurement form shall become, with the registration card, a permanent record of this model yacht.

1.9 The AMYA Star 45 Class recognizes and approves the molds and manufacturer and/or kit packagers of Star 45 molded hulls and kits in existence at the time of approval of these specifications. These sources will be approved sources for the class. New manufacturers will be directed to submit the first of their product to the Class Secretary for approval.

1.10 No maximum weight is specified, however, no yacht will weigh less than 12 pounds when fully rigged ready to sail. This means with all gear, rigging, sails, radio components, batteries and ballast placed and secured on board.

1.11 Bow Bumpers are mandatory for all class registered STAR 45 yachts. Bow bumpers are limited to three eight's of an inch (3/8") overhang. Bow bumpers shall be excluded in the overall length measurement, whether recessed in or otherwise attached to the bow stem. Bow bumpers must be of resilient fabrication to minimize damage to another yacht in the event of a collision.

I build hulls from cedar rather than balsa. I find a clear, straight grained dog-eared fince picket at Lowes, Home Depot, etc. I cut the rough edges and flats off with a 10 inch table saw, rough cut the planks for the hull, then use a 3 inch table saw from Micro- mark to cut the final planks. I think that cedar is stronger than balse, and I don't think it soaks up as much epoxy. Epoxy is weight. My hulls weigh about the same as a fiberglass hull, and don't oil can.

The plastic sacks that the newspaper is in when it hits your drive is useful as gloves. The epoxy doesn't disolve them. Also, you can cut up the newspaper plastic sack and use to keep the hull from sticking to your clamps. These sacks are also good for picking up dog crap off your lawn, or any other nasty stuff. Just check for holes before using. :-)

AMYA Star 45 Class Rules, 2006, 1.0 Hull:

1.1 The Star 45 Class establishes as their approved plans a set of lines and drawings as the approved reference and construction plans for the class. These plans are scaled and appropriately modified for the use of modelers building a 45-inch model of the Star Boat. Existing plans supplied by kit manufacturers, etc. are grandfathered. New molds, plugs and scratch built models shall conform to the approved plans and specifications.

1.2 Hull length will be 45 inches (plus or minus one half (1/2) inch overall. (NOTE: this does not include any chain plate for backstay attachment, or 1/4 inch bow bumper if used. However, if the chain plate is attached to the transom or overhangs the transom, it may not extend beyond the transom more than 3/8 of a inch.) Hulls may not be less than 11 inches nor exceed 12 inches in beam when measured at the widest point on the deck. (Rubrails are not included in measuring but will not exceed 1/4 inch of thickness/width.)

1.3 In the event of a builder choosing to scratch or hand build a Star 45 Yacht, the builder must adhere to the class approved reference and construction drawings, as obtained from the AMYA Ships Store, as in the builders ability. A second consideration in scratch building is to ensure that safe and sound building practice be maintained.

1.4 All hulls will be constructed of wood or fiberglass or a combination of wood and fiberglass and be a minimum of 16 ounces when weighed before attachment of the deck and keel. This weight must be

verified by another member of the Star 45 Class using the Class Measurement Form.

1.5 Decks shall be constructed of wood, fiberglass or plastic laminate material.

1.6 All hulls shall be the standard hard-chine hull. Hulls may be built with a sheer at scale height or with a sheer no more than one inch higher than scale (when measured at the point of maximum depth of sheer.)

1.7 All fiberglass and wood hulls will have a name plate permanently attached to the inside of the hull so as to be seen when the hatch cover is removed.

1.8 At or before its first Sanctioned Regatta the newly built model yacht must be measured using, as reference, the approved measurement form and signed by not less than the owner of the model yacht and one other member of the class. This measurement form shall become, with the registration card, a permanent record of this model yacht.

1.9 The AMYA Star 45 Class recognizes and approves the molds and manufacturer and/or kit packagers of Star 45 molded hulls and kits in existence at the time of approval of these specifications. These sources will be approved sources for the class. New manufacturers will be directed to submit the first of their product to the Class Secretary for approval.

1.10 No maximum weight is specified, however, no yacht will weigh less than 12 pounds when fully rigged ready to sail. This means with all gear, rigging, sails, radio components, batteries and ballast placed and secured on board.

1.11 Bow Bumpers are mandatory for all class registered STAR 45 yachts. Bow bumpers are limited to three eight's of an inch (3/8") overhang. Bow bumpers shall be excluded in the overall length measurement, whether recessed in or otherwise attached to the bow stem. Bow bumpers must be of resilient fabrication to minimize damage to another yacht in the event of a collision.

Star 45 R/C model sail boat | DECK

Phil Geren on Staining Wood Deck Materials:

I was planning to stain planks prior to assembly, then use CA first, to get things fitted together and in place, then cover with 0.25 oz. fiberglass cloth and "thinned" (MEK or IPA) epoxy. Flex Coat epoxy people (fishing rod mfgrs) recommend heating the epoxy surface with a heat gun (hot air) prior to it's hardening, to release bubbles and smooth the surface, like what you see on fine fishing rods.

AMYA Star 45 Class Rules, 2006, DECK

8.1 Deck construction shall be limited to wood, plywood, fiberglass reinforced plastic or plastic

laminations (Formica). It may be covered with any material. Thin plastic films, such as MonoKote,

are not allowed for decks except as coverings.

8.2 Hatches are not restricted in size, location, number or style, as long as deck strength and

integrity are maintained.

I was planning to stain planks prior to assembly, then use CA first, to get things fitted together and in place, then cover with 0.25 oz. fiberglass cloth and "thinned" (MEK or IPA) epoxy. Flex Coat epoxy people (fishing rod mfgrs) recommend heating the epoxy surface with a heat gun (hot air) prior to it's hardening, to release bubbles and smooth the surface, like what you see on fine fishing rods.

AMYA Star 45 Class Rules, 2006, DECK

8.1 Deck construction shall be limited to wood, plywood, fiberglass reinforced plastic or plastic

laminations (Formica). It may be covered with any material. Thin plastic films, such as MonoKote,

are not allowed for decks except as coverings.

8.2 Hatches are not restricted in size, location, number or style, as long as deck strength and

integrity are maintained.

Star 45 R/C model sail boat | Sails

AMYA Star 45 Class Rules, 2006, Sails

2.1 Sails may be of single or multi-paneled construction. Sail material shall be unrestricted.

2.2 All sails are to be cut to comply with the following maximum dimensions when measured by the procedure as outlined in the "AMYA Regulations". Dimensions shown are measured 'Edge of Cloth" to "Edge of Cloth" and are in inches.

2.3

MAIN JIB

Luff 62.75 42.50

Foot 25.50 15.75

Leech 65.50 37.00

Roach 2.00 0.50

Head 0.75 0.75

Foot Round 0.50 0.50

2.4 All sails, main and jib, will be cut with either a straight head to clew leech with no roach, or a fair

curved head to clew leech with the maximum roach point occurring approximately one half the distance from the clew to head. Divide a straight line from the aft corners of the Clew and Head into four (4) equal sections. Then, for the Main Sail, maximum offset from edge of cloth for the Roach at the quarter points to be 1.75" and the offset at the mid-point to be 2.0". For the Jib, the offset at the quarter points to be 0.375" and at the mid-point to be 0.50". Sails cut with a straight leech at the maximum roach allowance are prohibited from use on the Star 45 Class Yacht.

2.5 The mainsail gooseneck or attachment will be attached to the Mast between 0.50 inch minimum to 4.0 inch maximum measured from the deck.

2.6 Battens are allowed on the mainsail but are restricted to 4 in number, equally spaced along the leech and may not exceed 8.50 inches in length. Battens are not permitted in the jib sail.

2.7 Sailmakers must conform to the above measurements.

9.1 Each yacht shall carry on her main sail the class 5 point "STAR EMBLEM" and an assigned AMYA registration number. The star shall be at least 2 inches in size (measured from point to point across the flat of the star) and positioned above the registration number. Registration numbers shall be at least 3 inches in height and at least 3/8 inch thick. Both star and registration numbers will be placed on the upper half of the mainsail on both port and starboard sides of the mainsail and shall be positioned so as to be easily read from either side.

2.1 Sails may be of single or multi-paneled construction. Sail material shall be unrestricted.

2.2 All sails are to be cut to comply with the following maximum dimensions when measured by the procedure as outlined in the "AMYA Regulations". Dimensions shown are measured 'Edge of Cloth" to "Edge of Cloth" and are in inches.

2.3

MAIN JIB

Luff 62.75 42.50

Foot 25.50 15.75

Leech 65.50 37.00

Roach 2.00 0.50

Head 0.75 0.75

Foot Round 0.50 0.50

2.4 All sails, main and jib, will be cut with either a straight head to clew leech with no roach, or a fair

curved head to clew leech with the maximum roach point occurring approximately one half the distance from the clew to head. Divide a straight line from the aft corners of the Clew and Head into four (4) equal sections. Then, for the Main Sail, maximum offset from edge of cloth for the Roach at the quarter points to be 1.75" and the offset at the mid-point to be 2.0". For the Jib, the offset at the quarter points to be 0.375" and at the mid-point to be 0.50". Sails cut with a straight leech at the maximum roach allowance are prohibited from use on the Star 45 Class Yacht.

2.5 The mainsail gooseneck or attachment will be attached to the Mast between 0.50 inch minimum to 4.0 inch maximum measured from the deck.

2.6 Battens are allowed on the mainsail but are restricted to 4 in number, equally spaced along the leech and may not exceed 8.50 inches in length. Battens are not permitted in the jib sail.

2.7 Sailmakers must conform to the above measurements.

9.1 Each yacht shall carry on her main sail the class 5 point "STAR EMBLEM" and an assigned AMYA registration number. The star shall be at least 2 inches in size (measured from point to point across the flat of the star) and positioned above the registration number. Registration numbers shall be at least 3 inches in height and at least 3/8 inch thick. Both star and registration numbers will be placed on the upper half of the mainsail on both port and starboard sides of the mainsail and shall be positioned so as to be easily read from either side.

Star 45 R/C model sail boat | Mast and Boom

AMYA Star 45 Class Rules, 2006, Mast and Boom

3.1 Masts shall be made of wood or aluminum. Swing rigs, rotating and permanently bent masts are prohibited.

3.2 Masts shall not exceed 3/4 inches square when measured at the thickest point of the mast. Maximum mast height shall be 70" when measured from the deck, inclusive of the crane. Rotating wind indicators and burgee staffs are not included provided the backstay is not attached to them in order to circumvent the 70" maximum mast height specification.

4.0 BOOMS:

4.1 The main boom and jib club shall not exceed 5/8" when measured at the thickest point. Booms and jib clubs shall be constructed of wood, aluminum and/or fiberglass.

3.1 Masts shall be made of wood or aluminum. Swing rigs, rotating and permanently bent masts are prohibited.

3.2 Masts shall not exceed 3/4 inches square when measured at the thickest point of the mast. Maximum mast height shall be 70" when measured from the deck, inclusive of the crane. Rotating wind indicators and burgee staffs are not included provided the backstay is not attached to them in order to circumvent the 70" maximum mast height specification.

4.0 BOOMS:

4.1 The main boom and jib club shall not exceed 5/8" when measured at the thickest point. Booms and jib clubs shall be constructed of wood, aluminum and/or fiberglass.

Star 45 R/C model sail boat | Rudder

AMYA Star 45 Class Rules, 2006, Rudder

6.1 Rudders may be constructed of wood, fiberglass, plastic, plastic laminates or metal. The exact shape is not specified, but they may not exceed 4 1/2 inches at the hull (fore and aft) 3 inches at the bottom, (fore and aft); and may not project more than 7 inches below the hull when measured at the post..

6.1 Rudders may be constructed of wood, fiberglass, plastic, plastic laminates or metal. The exact shape is not specified, but they may not exceed 4 1/2 inches at the hull (fore and aft) 3 inches at the bottom, (fore and aft); and may not project more than 7 inches below the hull when measured at the post..

Star 45 R/C model sail boat | Keels and keel-ballast bulbs

AMYA Star 45 Class Rules, 2006, KEELS AND BALLAST BULBS

7.1 Keel will be of the style known as drop, and will be of the FIN and BULB type.

7.2 Keel fins may be solid or hollow and constructed of reinforced plastic, plastic laminates, fiberglass, wood or metal. (Note: Strength and integrity of the keel fins must be maintained whether built solid or hollow.) Keel fin shape is not specified but must follow the general shapes outlined on the reference drawing. However, keels will not be less than 6 inches nor more than 8 inches long (Fore and Aft) at the keel/hull junction, nor less than 4 inches nor more than 6 inches long (Fore and Aft) at the keel/ballast bulb junction.

7.3 Keels, keel fins and ballast bulbs may be removable, however, they may not be changed, interchanged, substituted or otherwise manipulated once any heat or series of heats in which scores will be compiled, has started. Mechanically movable keels or ballast bulbs are specifically prohibited from use in Star 45 Class Yachts.

7.4 Ballast bulbs may be constructed of any material not prohibited by the AMYA. The actual shape is left to the builder's discretion, but will not exceed 9.75 (9 3/4) inches from the front of the keel bulb to the rearmost point of the keel or bulb.

7.5 Total drop (length) of the keel fin/ballast bulb combination will not exceed 11.5 (11 1/2) inches when measured from the keel/hull junction, before any fillers or streamlining is added.

7.6 Ballast may be made from any readily available material, such as poured lead, lead shot, etc. (Note: When using material such as lead shot, the mass must be solidified through the use of a bonding agent such as fiberglass or epoxy resin, plaster of paris, poured over and through in order to create a solid mass.)

7.7 Race directors may elect to use a template based on the construction plans to determine the keel length (depth).

7.8 Keel depth shall be measured from the center of the keel fin at the hull to the bottom of the ballast bulb. This measurement is from the edge of the bottom of the hull as it meets the side of the keel and should be determined during construction and before any fillet or fairing is added.

7.9 The Star 45 Class specifically excludes radio equipment, sail controls and batteries (power cells) from being considered ballast. This specification defines ballast as anything carried aboard the model for the main purpose of changing the weight distribution of the model and/or weight of the model. Ballast shall be fixed in place by gluing, fiberglassing, or bolting (bolts and screws).

7.9.1 Ballast may not be removed or relocated during any one regatta. The use of Velcro or similar quick release fasteners is prohibited as methods of mounting ballast.

7.1 Keel will be of the style known as drop, and will be of the FIN and BULB type.

7.2 Keel fins may be solid or hollow and constructed of reinforced plastic, plastic laminates, fiberglass, wood or metal. (Note: Strength and integrity of the keel fins must be maintained whether built solid or hollow.) Keel fin shape is not specified but must follow the general shapes outlined on the reference drawing. However, keels will not be less than 6 inches nor more than 8 inches long (Fore and Aft) at the keel/hull junction, nor less than 4 inches nor more than 6 inches long (Fore and Aft) at the keel/ballast bulb junction.

7.3 Keels, keel fins and ballast bulbs may be removable, however, they may not be changed, interchanged, substituted or otherwise manipulated once any heat or series of heats in which scores will be compiled, has started. Mechanically movable keels or ballast bulbs are specifically prohibited from use in Star 45 Class Yachts.

7.4 Ballast bulbs may be constructed of any material not prohibited by the AMYA. The actual shape is left to the builder's discretion, but will not exceed 9.75 (9 3/4) inches from the front of the keel bulb to the rearmost point of the keel or bulb.

7.5 Total drop (length) of the keel fin/ballast bulb combination will not exceed 11.5 (11 1/2) inches when measured from the keel/hull junction, before any fillers or streamlining is added.

7.6 Ballast may be made from any readily available material, such as poured lead, lead shot, etc. (Note: When using material such as lead shot, the mass must be solidified through the use of a bonding agent such as fiberglass or epoxy resin, plaster of paris, poured over and through in order to create a solid mass.)

7.7 Race directors may elect to use a template based on the construction plans to determine the keel length (depth).

7.8 Keel depth shall be measured from the center of the keel fin at the hull to the bottom of the ballast bulb. This measurement is from the edge of the bottom of the hull as it meets the side of the keel and should be determined during construction and before any fillet or fairing is added.

7.9 The Star 45 Class specifically excludes radio equipment, sail controls and batteries (power cells) from being considered ballast. This specification defines ballast as anything carried aboard the model for the main purpose of changing the weight distribution of the model and/or weight of the model. Ballast shall be fixed in place by gluing, fiberglassing, or bolting (bolts and screws).

7.9.1 Ballast may not be removed or relocated during any one regatta. The use of Velcro or similar quick release fasteners is prohibited as methods of mounting ballast.

7/05/2006

Making a keel mold

From Jim Adams:

I made a plug from balsa and finished it to a smooth finish second I used two aluminum pans (the kind that you throw away) I filled the first one with plaster took the bulb (well waxed) and placed it in the plaster half way in I used two pins through the center to hold it down. let that dry then pull out the plug next put thin saran wrap over the mold and place the plug back in the hole.

Now comes the fun part I used rubber bands to hold the plug in place (remember I had two pins that extend past the mold walls) next fill the second pan with plaster and lay the first on top it is kind of messy but it works. When the second half dries (about two hours) pull them apart. You will need to plug the holes at the ends on the sides and create small air path upward in the and a spur (looks like a funnel when you

are dune this needs to be big enough to pour in the led) at the end.

I made a plug from balsa and finished it to a smooth finish second I used two aluminum pans (the kind that you throw away) I filled the first one with plaster took the bulb (well waxed) and placed it in the plaster half way in I used two pins through the center to hold it down. let that dry then pull out the plug next put thin saran wrap over the mold and place the plug back in the hole.

Now comes the fun part I used rubber bands to hold the plug in place (remember I had two pins that extend past the mold walls) next fill the second pan with plaster and lay the first on top it is kind of messy but it works. When the second half dries (about two hours) pull them apart. You will need to plug the holes at the ends on the sides and create small air path upward in the and a spur (looks like a funnel when you

are dune this needs to be big enough to pour in the led) at the end.

Star 45 R/C model sail boat , making a keel bulb mold and Castings

From Jim Adams:

I made a plug from balsa and finished it to a smooth finish second I used two aluminum pans (the kind that you throw away) I filled the first one with plaster took the bulb (well waxed) and placed it in the plaster half way in I used two pins through the center to hold it down. let that dry then pull out the plug next put thin saran wrap over the mold and place the plug back in the hole.

Now comes the fun part I used rubber bands to hold the plug in place (remember I had two pins that extend past the mold walls) next fill the second pan with plaster and lay the first on top it is kind of messy but it works. When the second half dries (about two hours) pull them apart. You will need to plug the holes at the ends on the sides and create small air path upward in the and a spur (looks like a funnel when you

are dune this needs to be big enough to pour in the led) at the end.

Billie Geisler's comments regarding "Keel Bulbs 2006 August 1:

I advise against using tire weights for ballast bulbs, because the tire weights seem to be some sort of alloy, and not pure lead. The markings on the weights are a good indicator, as different physically sized weights have the same ounce values stamped on them. So, if you use tire weights, you will have a physically larger bulb to achieve the necessary weight, thus more wetted surface friction, resistance through the water.

I go to the plumbing supply store to buy lead. This lead is much denser than tire weights. The lead comes in various shapes, some like hocky pucks, and some like Snickers bars. The Snickers bars fit into my lead pot better.

Incidentally, fishing supply stores sometimes carry electric lead pots, along with fishing weight molds. Good use for your tire weights. I was lucky enough to find a lead pot at a garage sale, sold by a rifleman who no longer cast his own bullets.

Consider mounting the ballast bulb on the keel fin at an angle, about 1 to 3 degrees up at the front. You can find info on performance of this arrangement on some IOM sites. It makes a substantial difference in boat speed on an IOM.

I cast my bulbs in two plaster of paris molds. One mold for the outer cheeks of the bulb(split fore and aft), and one for a center peice, to go between the cheeks. The thin (about 1/8 inch thick) center peice can be easily cut for fitting the fin, and drilled for adjusting the weight. If I need filler, I mix buckshot with epoxy. I can rough sand the lead with a belt sander, with very course belt. The course belt doesn't fill with lead.

I made a plug from balsa and finished it to a smooth finish second I used two aluminum pans (the kind that you throw away) I filled the first one with plaster took the bulb (well waxed) and placed it in the plaster half way in I used two pins through the center to hold it down. let that dry then pull out the plug next put thin saran wrap over the mold and place the plug back in the hole.

Now comes the fun part I used rubber bands to hold the plug in place (remember I had two pins that extend past the mold walls) next fill the second pan with plaster and lay the first on top it is kind of messy but it works. When the second half dries (about two hours) pull them apart. You will need to plug the holes at the ends on the sides and create small air path upward in the and a spur (looks like a funnel when you

are dune this needs to be big enough to pour in the led) at the end.

Billie Geisler's comments regarding "Keel Bulbs 2006 August 1:

I advise against using tire weights for ballast bulbs, because the tire weights seem to be some sort of alloy, and not pure lead. The markings on the weights are a good indicator, as different physically sized weights have the same ounce values stamped on them. So, if you use tire weights, you will have a physically larger bulb to achieve the necessary weight, thus more wetted surface friction, resistance through the water.

I go to the plumbing supply store to buy lead. This lead is much denser than tire weights. The lead comes in various shapes, some like hocky pucks, and some like Snickers bars. The Snickers bars fit into my lead pot better.

Incidentally, fishing supply stores sometimes carry electric lead pots, along with fishing weight molds. Good use for your tire weights. I was lucky enough to find a lead pot at a garage sale, sold by a rifleman who no longer cast his own bullets.

Consider mounting the ballast bulb on the keel fin at an angle, about 1 to 3 degrees up at the front. You can find info on performance of this arrangement on some IOM sites. It makes a substantial difference in boat speed on an IOM.

I cast my bulbs in two plaster of paris molds. One mold for the outer cheeks of the bulb(split fore and aft), and one for a center peice, to go between the cheeks. The thin (about 1/8 inch thick) center peice can be easily cut for fitting the fin, and drilled for adjusting the weight. If I need filler, I mix buckshot with epoxy. I can rough sand the lead with a belt sander, with very course belt. The course belt doesn't fill with lead.

7/04/2006

Thinning Epoxy

In a post to Yahoo Star 45 Groups Terry Forbes reveals his method for thinning epoxy so that it soaks, as a first coat, thoroughly into basswood planked decks he builds.

He adds 90% isopropyl alcohol ('rubbing" alcohol) to mixed epoxy, using an eyedropper, until the viscosity is what he wants.

Apparently, this does not adversely affect curing.

I find this fascinating and useful info.

He adds 90% isopropyl alcohol ('rubbing" alcohol) to mixed epoxy, using an eyedropper, until the viscosity is what he wants.

Apparently, this does not adversely affect curing.

I find this fascinating and useful info.

Star 45 R/C model sail boat | decks made from bass wood strips

From Terry Forbes:

"The Star 45 boats that I have built have decks made from bass wood strips that are 1/4" X 1/16". I find them easy to use and easy to bend with out fracturing. I use thick ca to bond to hull frames and to the adjoining strip. When is have it all glued down, I sand with 120 grit and then 200. I use a soft rag to wipe off deck but leave the cracks filled with the sanding dust or "wood Flower" I then give it a thinned coat of slow cure epoxy. This first coat will soak into the wood completely. I then use un-thinned epoxy for the second and third coat, wet sanding and tack ragging between coats. If you want a really glassy deck, I use a finish coat of Captians Spar varnish. I have used this finish technique on full scale boats and all of my Kayaks. Very nice and durable finish. The decks go on easy and I try to stagger the strips one dark one light. I built a full scale star in the early 60's and had a striped planked deck. I like the look and it builds light. It keeps the hull true as sometimes when you add the deck using plywood it can cause it to move around. I will post some photos of my next hull as it comes to life. I have constructed a ships-way. I used the formers that are shown on the IMYA star plans. I now only have to cut the actual hull formers. I Stack cut 4 at a time on my trusty Dremmel Moto Shop Saw. I have added some lighting holes here and there. All in all I can have a hull lofted in 1 hr. and the sides on that evening using 20-min epoxy to coat the frames and the inside of the hull side. I first made my side peaces out of poster board. This allowed me to get the fit close and have a template to trace the sides for cutting. "

"I get all of my wood from Lone Star Balsa in Texas.. It is run by Riley Wooten "

"The Star 45 boats that I have built have decks made from bass wood strips that are 1/4" X 1/16". I find them easy to use and easy to bend with out fracturing. I use thick ca to bond to hull frames and to the adjoining strip. When is have it all glued down, I sand with 120 grit and then 200. I use a soft rag to wipe off deck but leave the cracks filled with the sanding dust or "wood Flower" I then give it a thinned coat of slow cure epoxy. This first coat will soak into the wood completely. I then use un-thinned epoxy for the second and third coat, wet sanding and tack ragging between coats. If you want a really glassy deck, I use a finish coat of Captians Spar varnish. I have used this finish technique on full scale boats and all of my Kayaks. Very nice and durable finish. The decks go on easy and I try to stagger the strips one dark one light. I built a full scale star in the early 60's and had a striped planked deck. I like the look and it builds light. It keeps the hull true as sometimes when you add the deck using plywood it can cause it to move around. I will post some photos of my next hull as it comes to life. I have constructed a ships-way. I used the formers that are shown on the IMYA star plans. I now only have to cut the actual hull formers. I Stack cut 4 at a time on my trusty Dremmel Moto Shop Saw. I have added some lighting holes here and there. All in all I can have a hull lofted in 1 hr. and the sides on that evening using 20-min epoxy to coat the frames and the inside of the hull side. I first made my side peaces out of poster board. This allowed me to get the fit close and have a template to trace the sides for cutting. "

"I get all of my wood from Lone Star Balsa in Texas.. It is run by Riley Wooten "

7/02/2006

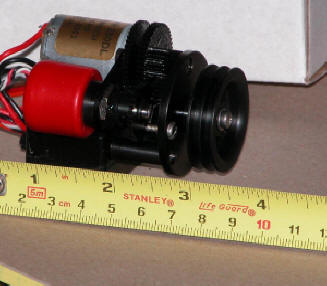

HiTec HS-725 or HS-785 Winches | SCU's

From: "Stephen Pratt" :

"On the North Coast (Ohio), are using HiTec HS-725 or HS-785 Winches. Bob Luther developed a mechanism to work an endless loop system of sail control. Fits inside the Star 45 with plenty room to spare."

how much weight/advantage can be gained by using a lighter hull?

From "Larry Ludwig"

"If you are dealing with a 16 ounce hull, how much weight/advantage can be gained by using a lighter hull?

If you will test the boats with different keels, with as much as a 3 oz difference between hulls... you will find that there is virtually no noticeable, or measureable difference... and at that weight (3oz) you are 4 times the typical amount of error that would occur from weighing the keel while attached to the boat. This method has been used at many many regattas for 30 years and works well enough."

"If you are dealing with a 16 ounce hull, how much weight/advantage can be gained by using a lighter hull?

If you will test the boats with different keels, with as much as a 3 oz difference between hulls... you will find that there is virtually no noticeable, or measureable difference... and at that weight (3oz) you are 4 times the typical amount of error that would occur from weighing the keel while attached to the boat. This method has been used at many many regattas for 30 years and works well enough."

Weighing a keel while attached to a boat

From "Larry Ludwig"

"Weighing a keel while attached to a boat can be done with a high degree of accuracy. You can test this out on a boat with a removeable keel. Lay the boat on it's side with the keelbulb on the scale with the keel parallel to the table. Then take the keel off and weight it and you will be amazed that they are nearly the same, as in within 95% or better."

"Weighing a keel while attached to a boat can be done with a high degree of accuracy. You can test this out on a boat with a removeable keel. Lay the boat on it's side with the keelbulb on the scale with the keel parallel to the table. Then take the keel off and weight it and you will be amazed that they are nearly the same, as in within 95% or better."

Subscribe to:

Comments (Atom)